Indians also love to eat flour foods, all kinds of noodle products in India have a very large market. The new type stick noodle production line is developed based on the current demand for such products. India is the second most populous country in the world, and cheap food such as some noodles is widely sold in India.

DetailsAutomatic Stick Noodle Production Line

Automatic Stick Noodle Production Line,

1500 Type-Upgraded

Automatic Stick Noodle Production Line,

Standard Type

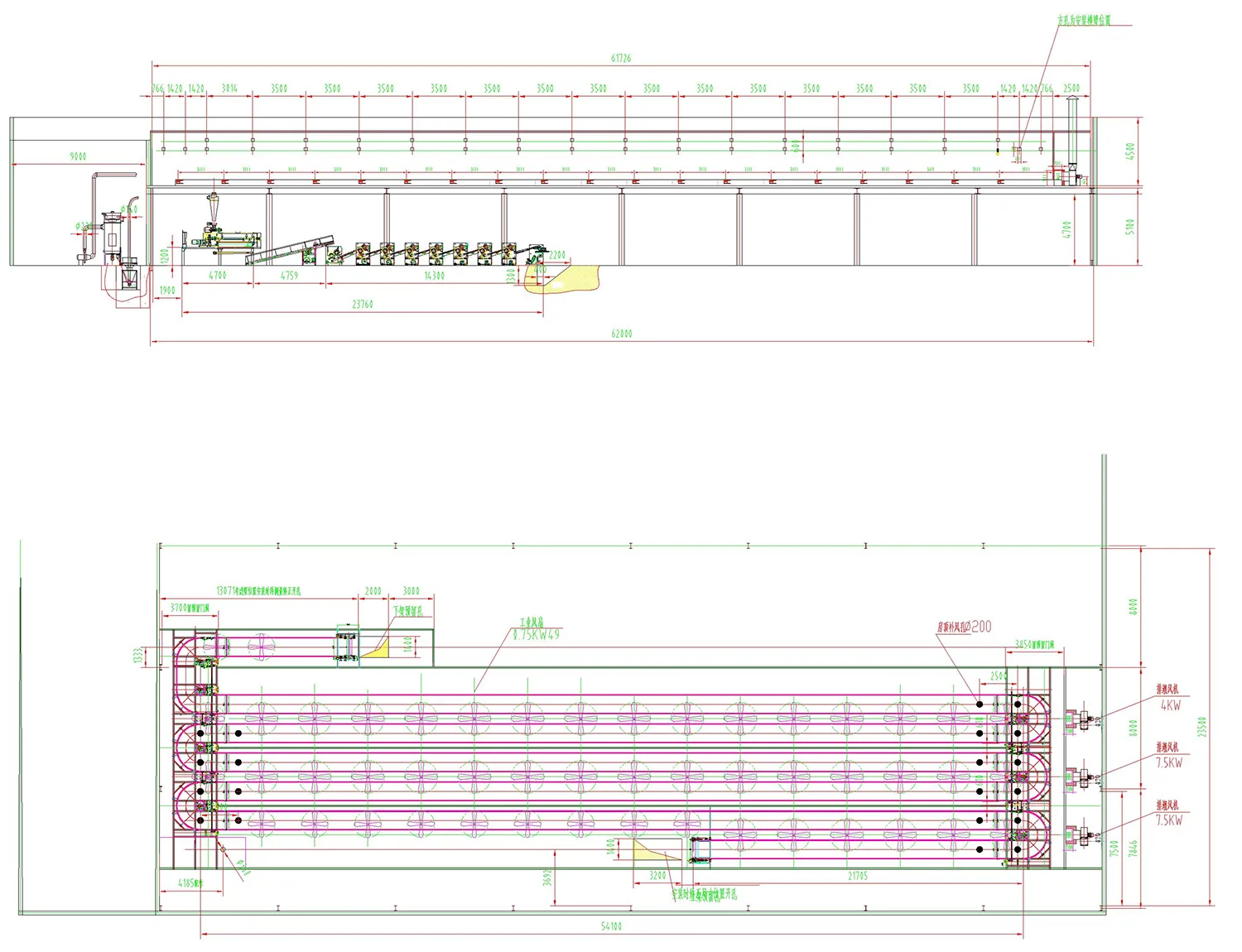

Two types of stick noodle production lines are provided by our company, which are divided into straight and curved type according to the transmission modes of noodle drying room. The drying room is available with straight chain and curved chain conveying. The stick noodle production line adopts low-temperature drying technology, providing drying time of about 4.5 hours.

The main features of the straight type stick noodle production line are: reasonable design, stable performance, compact structure, convenient operation, high degree of automation, small footprint, easy control of temperature and humidity, and capacity from 3 tons to 20 tons per 8 hours.

- Highly flexible design:

The equipment layout can be designed according to the customer's existing workshop. Due to curved conveying, the drying room can accommodate lots of noodles even in a space with limited length. With easy operation, the temperature and humidity can be automatically controlled. The capacity is optional from 3 tons to 30 tons per 8 hours. - High degree of automation:

With only 2 operators, the entire process from flour to noodle is completed automatically. The flour is supplied by air. Equipped with continuous dough mixer, the dough after ripening is directly conveyed to the pressing roller. After continuous rolling, the dough sheet is automatically cut into flat or round noodles, which automatically hangs on the rods to enter the drying room. The noodles are continuously dried in the drying room for 4.5 hours. The dried noodles are conveyed to the cutting machine for cut off, and then delivered to the weighing machine through the belt conveyor for final packaging. - Finished product diversity:

longevity noodles, egg noodles, chow mein, boiled noodles, etc.

- Features compact construction, and pleasing appearance

- Six-axis dough feeding is individually driven by the motor. The dough sheet thickness can be automatically adjusted. In addition, the dough sheet can be loaded in an automatic manner.

- The dough sheet cutting speed can be automatically tracked.

- The pressing roller is made of stainless steel, which is wear resistant and rust free. Made using polymer composite material, the scraper works under the controlled pressure, causing no damage to the pressing roller.

- Electrical parts come with digital control. Easy operation is achieved by touch screen and one-button operation.

-

Brine Mixer

Designed to prepare, cool and store brine solution, the brine mixer consists of a mixing barrel, agitator, heating tube, liquid pipe and feed liquid pump . It is used to prepare mixed liquids such as salt, alkali, additives and water required for dough mixing. Adopting brine mixer provides quick and simple producing of homogenous brine, without deposits with the use of dry substances.

-

Horizontal Continuous Mixer

The highly automatic continuous dough mixer can save labor and construction cost by combining screw feeding, water supplying, mixing and dough feeding together. The dough absorbs water fully and evenly.

-

1500 Type Press Roller

Rolling machine adopts different diameter rollers, is advantageous to the gluten forming; Ripple roller rolling makes the dough sheet draging in multi directions, which improves the dough sheet quality. Each roller adopts an independent motor, effectively ensuring the reliability of the transmission, and the structure is simplified, easy to maintenance.

-

Noodle Roller Cutter Storage Device

The noodle roller cutter storage device is convenient and quick to change the cutter within 2 minutes. The replacement can be completed in two minutes. Cutting and rod feeding machine adopts single transmisstion structure, which is controlled by PLC. The length of noodle is adjustable.

-

Swing Conveyor

Loading onto the drying rack by swing conveying is our company's latest technology. This new loading method simplifies the structure, overcomes the phenomenon of dislocation and falling of rods caused by chain stretching in traditional up-shelve, and has accurate alignment and zero rods falling.

-

Drying Room with Curved Conveyor

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying. The humidity and tempreture of each drying section is adjusted by frequency control, which is convenient and reliable. The reasonable drying room design makes the both end humidified air flow toward the middle, reducing the energy consumption of 20-30%.

-

Automatic Rod Return System

-

Noodle Packing Machine

Various types of packaging can be made by this noodle packing machine in a continuous and automatic manner. The finished instant noodle blocks can be packaged with paper cups/bowls, plastic bags, etc.

-

Electric Control Panel

The electric control panel is used as the main control of our instant noodle production lines.

-

Noodle Scrap Recycling System

After the noodle scrap fell, it is automatically pulverized, conveyed by air, automatically added to the flour in proportion, and entered into the dough mixing system, and no labor is needed during the period, which is safe, hygienic and automatic.

All versions include a device that captures the scraps and reintroduces them into the mixing tank.

-

Brine Mixer

Designed to prepare, cool and store brine solution, the brine mixer consists of a mixing barrel, agitator, heating tube, liquid pipe and feed liquid pump . It is used to prepare mixed liquids such as salt, alkali, additives and water required for dough mixing. Adopting brine mixer provides quick and simple producing of homogenous brine, without deposits with the use of dry substances.

-

Double-axis Mixer

The flour mixing machine is used for mixing and stirring flour and water. Dough mixing is the process of stirring flour and brine mixture in a certain proportion, so that the protein and starch in the flour absorb water and swell to form a flocculent dough. The flour mixer adopts a double-shaft structure, and the stirring paddle is in a spiral shape on the shaft. The two shafts rotate in opposite directions, so that the flour can fully absorb water and be uniform.

-

Dough Ripening Conveyor

The ripening conveyor ripens flour in a static state for a certain period of time, so that the dough fully absorbs water and the gluten quality of the dough improves.

-

Pressing Roller

Rolling machine adopts different diameter rollers, is advantageous to the gluten forming; Ripple roller rolling makes the dough sheet draging in multi directions, which improves the dough sheet quality. Each roller adopts an independent motor, effectively ensuring the reliability of the transmission, and the structure is simplified, easy to maintenance.

-

Drying Room

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying. The humidity and tempreture of each drying section is adjusted by frequency control, which is convenient and reliable. The reasonable drying room design makes the both end humidified air flow toward the middle, reducing the energy consumption of 20-30%.

-

Single-Blade Cutter

The noodle cutter features high level of automation. With the technology of speed adjusting system, noodle length can be controlled as desired.

-

Electric Control Panel

The electric control panel is used as the main control of our instant noodle production lines.

In May 2017, the general manager of Dongfang Group visited the old customer's company in Bangladesh and participated in the inspection and acceptance of stick noodle production line .

DetailsHenan Dongfang Noodle Machine Group Co., Ltd. has been specializing in the design and manufacture of noodle processing equipment since its establishment in 1975. Our noodle production equipment is highly praised by the instant noodle manufacturers, noodle production plants, dough processing factories, and other food machine manufacturers.

We have passed ISO9001 and CE certificate, and have more than 50 patent certificates. Our noodle production lines account for 65% of the Chinese market, and the top 10 Chinese noodle manufacturers have always been our partners.