This customer is from Japan. There is a huge demand for noodles in Japan's diet. Japan's population of more than 100 million provides a huge market for the sales of fresh noodles.

DetailsFresh Noodle Production Line

With adjustable noodle cutting length, the capacity of fresh noodle production line ranges from 200kg to 1500kg per hour. In order to meet the needs of processed product diversity, dumpling wrapper and wonton wrapper can also be made by the line in addition to producing fresh noodles. Multi-functional design significantly saves cost while meeting the need of product diversity.

Technical upgrade for the production process has been made on our fresh noodle production line. The advancements include double-sided sprinkling, twice ripening, corrugated roller rolling, and sterilization. This ensures that the fresh noodles produced are fresh and chewy, which is in line with people's pursuit of food safety, nutrition and health, and good taste. The shelf life can be greatly extended by means of additives, sterilization treatment, vacuum packaging, etc.

| Model | Production Capacity | Installed Capacity | Workshop L × W × H (m) |

| 300kg/h | 25kW | 20×5×6.5 | |

| 500kg/h | 35kW | 30×5×6.5 | |

| 800kg/h | 55kW | 35×5×6.5 | |

| 1000kg/h | 68kW | 40×6×7 | |

| 1200kg/h | 75kW | 50×6×7 | |

| 1500kg/h | 83kW | 60×7×7 |

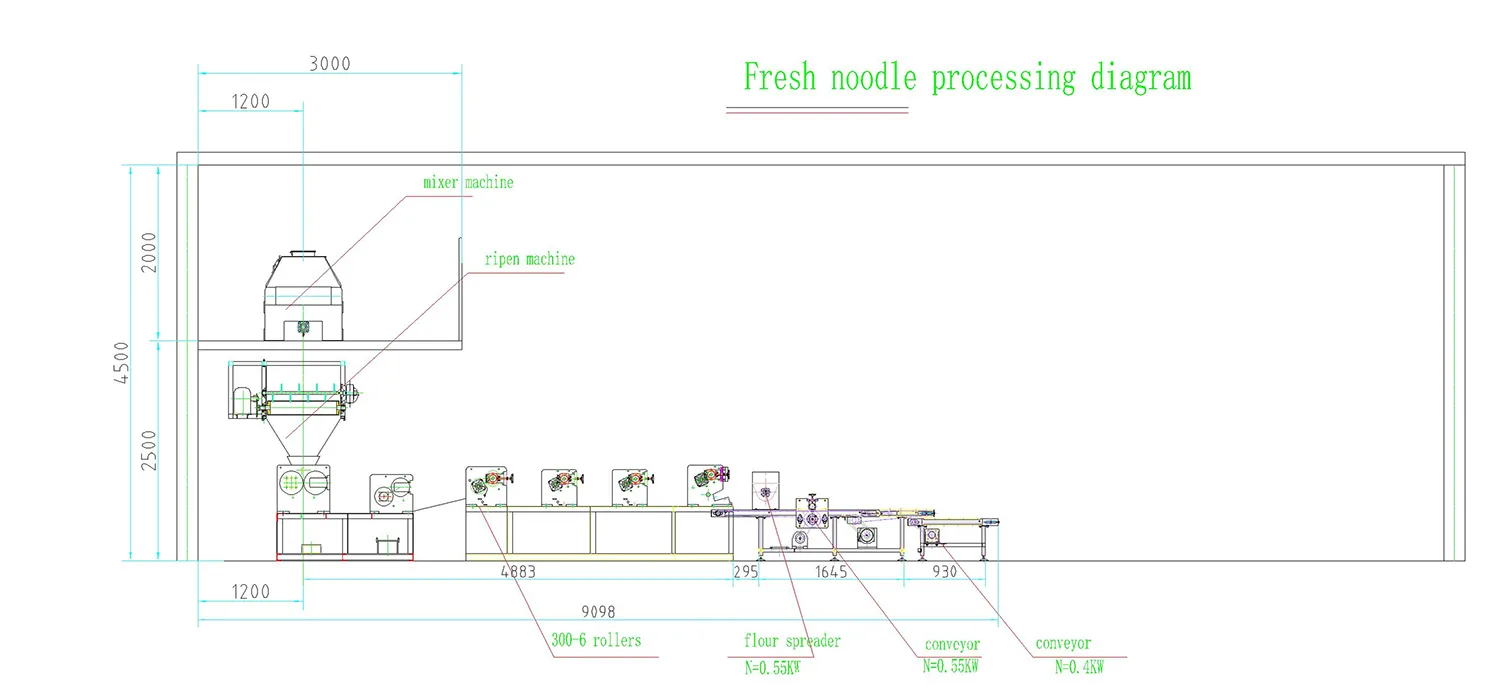

Layout 1: Suitable for a single -storey factory building with a height of 3-4m. This noodle production line comes with a length of 21m.

Layout 2: Suitable for a small factory with a floor height of 5m. This noodle production line features a curved conveyor with a length of 9.8m, which saves factory space.

-

Brine Mixer

Designed to prepare, cool and store brine solution, the brine mixer consists of a mixing barrel, agitator, heating tube, liquid pipe and feed liquid pump . It is used to prepare mixed liquids such as salt, alkali, additives and water required for dough mixing. Adopting brine mixer provides quick and simple producing of homogenous brine, without deposits with the use of dry substances.

-

Vacuum Dough Mixer

After the vacuum mixer is evacuated, the flour particles are fully expanded and absorb more water. The same account of flour can produce 5%-7% more dough. The noodles processed with this kind of dough have smooth taste, high transparency and good elasticity, which are the first choice for making fresh noodles.

-

Dough Ripen Conveyor

The dough ripening conveyor is used to manage the dough aging process after the dough mixing stage for your instant noodles. Maintaining constant temperature and humidity, the dough moves forward slowly with the conveyor belt in a static state , and achieves ripening naturally. When the dough reaches the end of the conveyor belt, the bar on the crushing device breaks the dough that may agglomerate into small pieces, and then falls into the hopper of the roller. The scraper sweeps off the dough stuck to the belt.

-

Pressing Roller

-

Flour Duster

-

Noodle Cutting Machine

The noodle cutter features high level of automation. With the technology of speed adjusting system, noodle length can be controlled as desired.

-

Noodle Rolling and Forming Machine

The processed noodles have various shapes, including straight, rolled, folded, and nest shape. Our company can form noodles by machinery instead of manual work, which is fast and requires less labor.

Henan Dongfang Noodle Machine Group Co., Ltd. has been specializing in the design and manufacture of noodle processing equipment since its establishment in 1975. Our noodle production equipment is highly praised by the instant noodle manufacturers, noodle production plants, dough processing factories, and other food machine manufacturers.

We have passed ISO9001 and CE certificate, and have more than 50 patent certificates. Our noodle production lines account for 65% of the Chinese market, and the top 10 Chinese noodle manufacturers have always been our partners.